What is Dwell Management and Current Limiting?

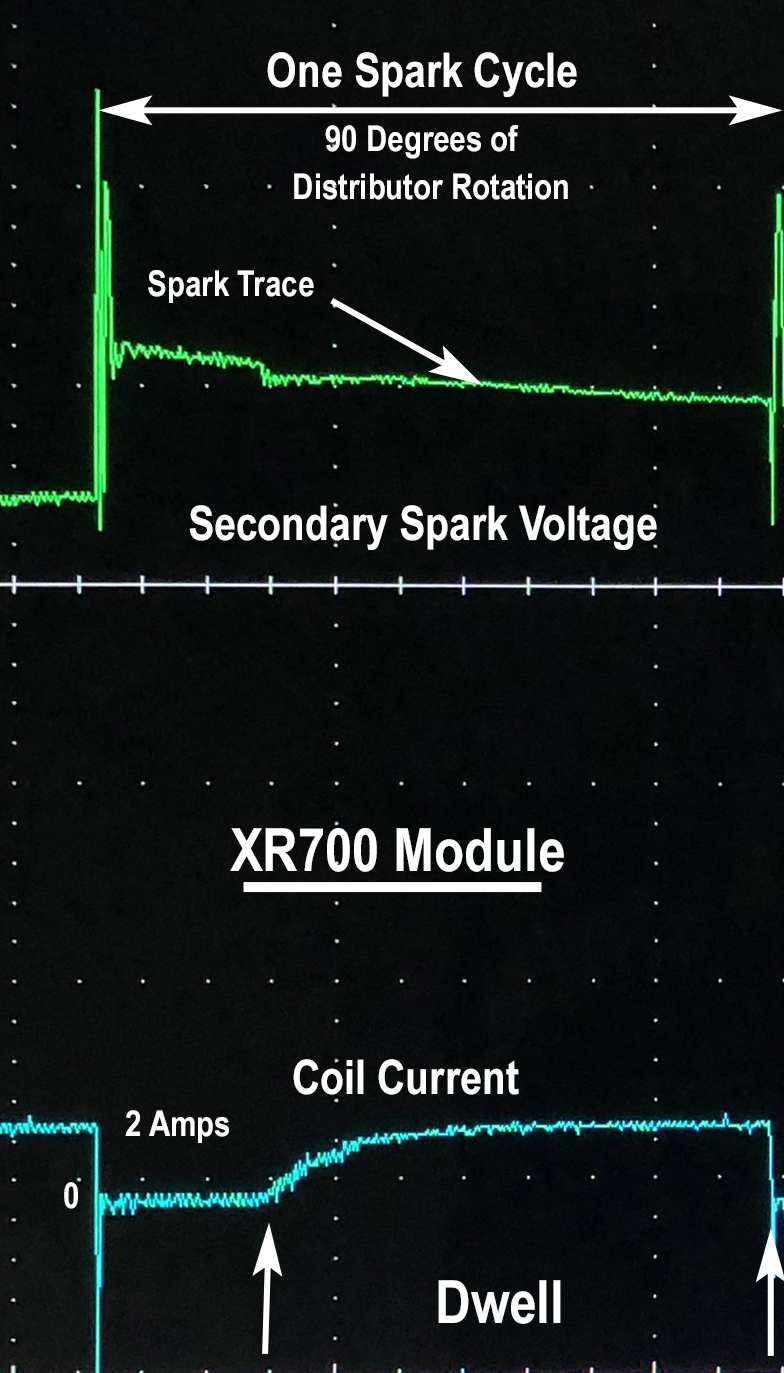

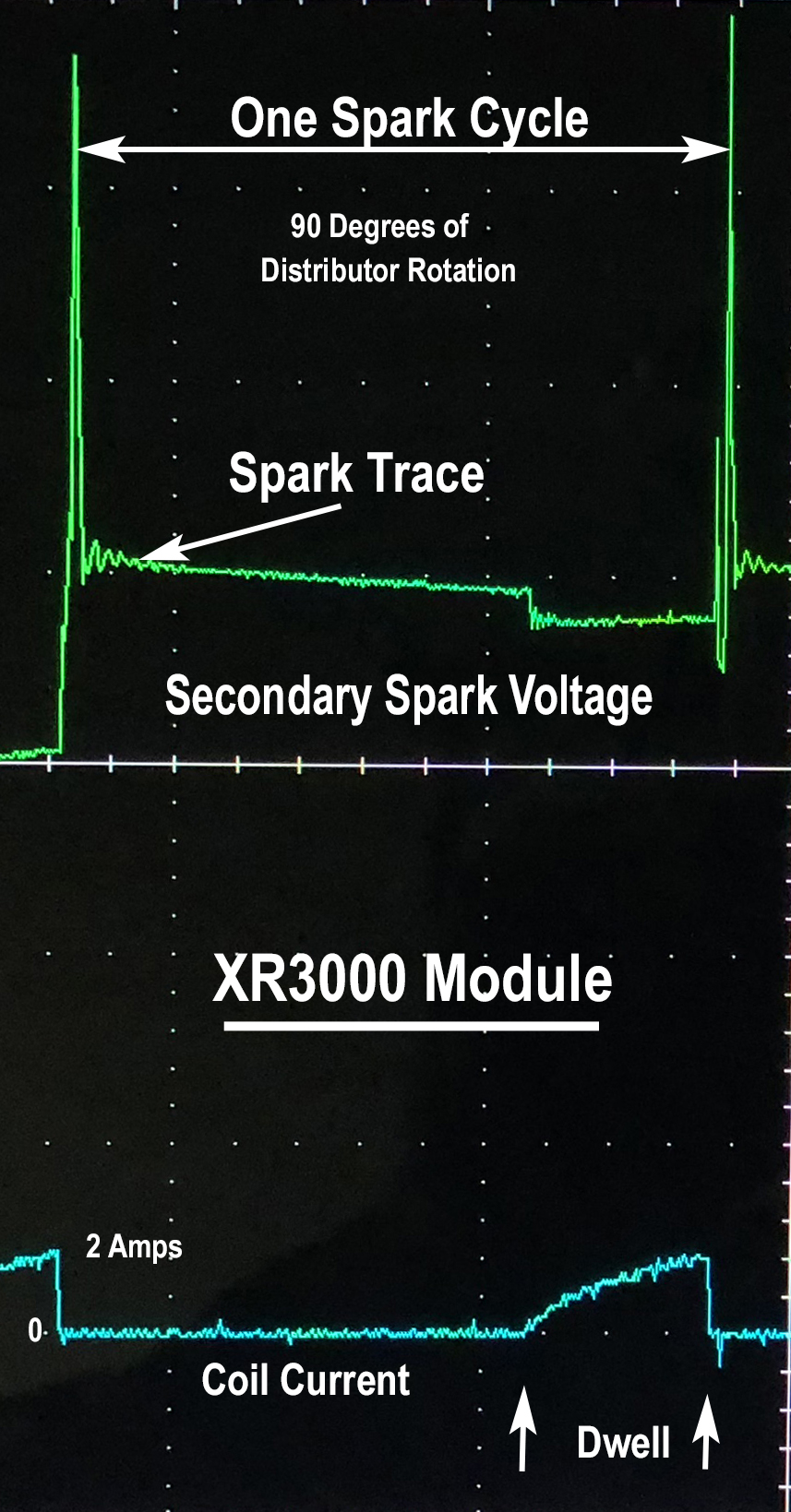

Just what is "Dwell" when referring to the ignition system in an internal combustion engine and why does it matter? Dwell is traditionally referred to as an angle but for this explanation, Dwell can be defined as the time during an ignition "cycle" that current is flowing into the ignition coil. The images on the left and right are Oscilloscope traces I made of what is going on electrically in a 3.8 Ohm ignition coil during the interval between the generation of sparks when running at 1440 RPM. If you assume that the graphs are representative of a 4 cylinder engine, then the 90 degrees of rotation of the distributor shaft represents the activity within the coil for one cylinder to receive its spark. On the "blue" current curve of each image, the arrow to the left and thus the point where the curve starts to go up, is the point at which current is allowed to flow into the primary windings of the coil. This is the beginning of the Dwell period. Current continues to flow as you progress to the right until you come to the next arrow. At this point current is abruptly stopped and the Dwell period ends. Here the coil windings are fully "saturated" and the abrupt termination of the flow of current causes the generation of a very high voltage discharge from the secondary winding which is the "spark" that goes to a sparkplug. As you progress further to the right, the voltages in the coil windings decay to a steady state until such time as the next "cycle" starts when current is allowed to flow into the coil again. By comparing the current curve in the two images, you can readily see that there is a significant difference in the Dwell period that is controlled by the two different electronic control modules. As far as Dwell angle, the XR700 is about 67° and the XR3000 is about 26° at 1440 RPM.

In a basic points type ignition system, the Dwell is determined by the gap between the contacts on the points. Once the gap is established, the dwell is fixed and does not change (except for wear of the components). Essentially this fixed Dwell concept is found in most of the electronic ignition units such as the Pertronix Ignitor and Crane/FAST XR700 units. In the original design of all of these units, the guiding principle of operation was that the Dwell period must be sufficiently long such that full saturation of the coil will occur at the design maximum RPM. Since the Dwell is fixed, more current than is necessary flows into the coil at all lower RPM and thus adds to the heat generated within the coil. This is especially problematic for the Atomic 4 engine due to the fact that it is a 4 cylinder engine and also has a low operating RPM range. These have been major factors contributing to the coil heating and many failures that have been experienced over the years.

The images above are actual Oscilloscope traces made using the same coil, trigger mechanism, and voltage source but with an XR700 module and an XR3000 module respectively. The XR3000 electronic ignition module has a unique Dwell Management feature that adjusts the Dwell as a function of speed whereas the XR700 has a very long and fixed Dwell. With the ability to adjust Dwell, the Dwell angle actually becomes Dwell Time. Consider this, for a fixed Dwell angle the time that current flows gets shorter the higher the RPM. Ideally with Dwell Management you would like to have the Dwell time constant from idle to maximum RPM and thus assure that the coil just gets fully saturated over the entire RPM range. The XR3000 comes pretty close to doing exactly that and thus prevents essentially all coils from overheating with NO BALLAST RESISTOR needed while still providing an excellent spark. Note: The Dwell is NOT user adjustable. Dwell is varied by the microprocessor ONLY.

Another remarkable feature of the new XR3000 electronic ignition module is a function known as "Current Limiting". This is an especially useful feature in that it allows the use of a very low primary resistance high performance coil (.4 - .5 Ohms) which can saturate quickly and always produce an excellent spark. The "Current Limit" feature mainly comes into play in the lower RPM ranges where there is plenty of time for coil saturation even with a reduced dwell angel. A more relevant side benefit of "Current Limiting" is the feature that the module will completely shut off current to the coil in the event that the ignition switch is on yet the engine is NOT running! No more burned up coils and/or modules due to a simple oversight when doing maintenance.