|

|

As part of our ongoing program of Continuous Improvement, we have refined the geometry of the Indigo Atomic 4 propeller to yield a propeller that is even quieter and smoother than the original model with slightly higher Wide Open Throttle (WOT) RPM to boot. The "Radial Winglet" name refers to the change that has been made to the geometry of the winglet. The fillet that defines the transition from the blade face to the winglet in now on a constant radius. This moves the suction side of the winglet (forward side) to a location that limits the impact of tip vortex cavitation on that side of the winglet thus reducing noise in the normal cruising RPM range.

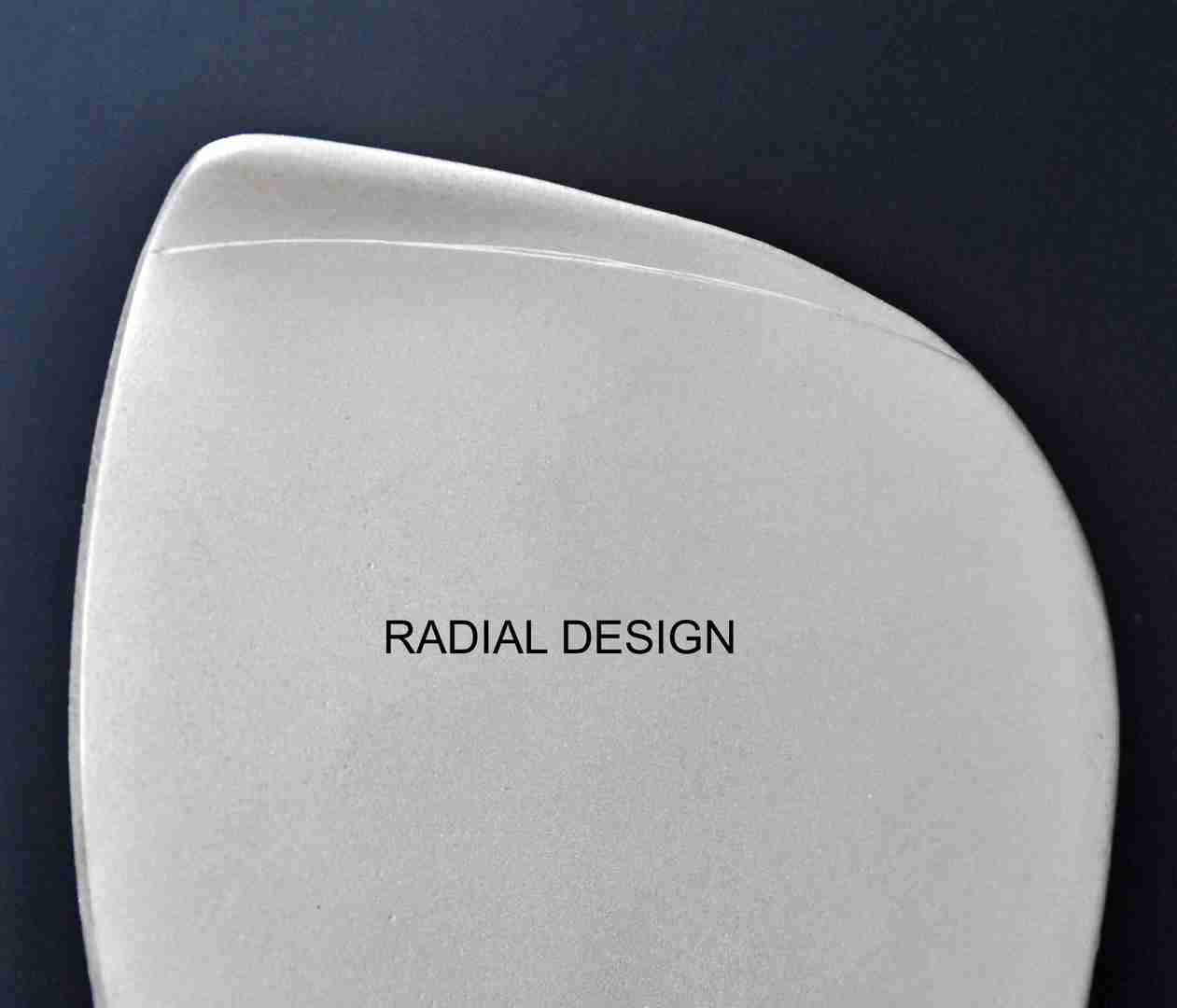

Shown here are images of the old and new blades to give you an idea of the subtle differences. The "scratch" on each blade near the winglet is a scribe mark that was made at a constant radius about the center of the propeller bore. As you can see on the "Original Design", the winglet sort of flared out as you traveled from the leading edge (right side) to the trailing edge (left side). In the "Radial Design", the flare is gone and the fillet radius between the blade and the winglet is on a constant radius from the leading edge to the trailing edge. Admittedly, this does not really look like any big deal. However, it turns out to be rather significant from a torque and noise standpoint. By "rolling" the trailing edge portion of the winglet toward the propeller centerline, we were able to remove about 3/16" of winglet (at the greatest propeller radius) to obtain the configuration shown at the right. This reduction in blade area at the extreme radius plus the radial progression of the winglet fillet radius yielded a WOT increase of nearly 300 RPM in initial testing. This increase of RPM was accompanied by a very slight reduction in thrust so a small change in pitch has also been made.

Aside from this subtle change in geometry, the Indigo propeller remains the only propeller designed from the ground up to improve performance of the Direct DriveAtomic 4 powered yacht. The design of this propeller has evolved from numerous tests with a variety of 2 and 3 blade designs, all with the Direct Drive Atomic 4 as the engine of choice. Note: Some V-Drive Atomic 4 models are direct drive in that they have a 1:1 reduction. Check name plate on V-drive for ratio. Engines with a reduction gear (not Direct Drive) are unique in that the propeller shaft coupling has four (4) bolts where as the Direct Drive coupling has only three (3) bolts.

The vast majority of Direct Drive Atomic 4

yachts were originally equipped with a 2 blade, 12" diameter by about

9" pitch propeller. This application allows the vessel to achieve a

respectable cruise speed in calm waters at about 1400 RPM. However, wide

open throttle is only about 1700 RPM which leaves very little reserve for foul

weather or bottom fouling. Furthermore, at 1400 RPM, the engine is

working very hard (near maximum cylinder pressure) which leads to high loads on

rings, pistons, and bearings.

We finally found a foundry to cast props using C873 Silicon Bronze

The normal installation procedure for the Indigo Prop is the same as with any propeller. Install it on its shaft with a shaft zinc on the shaft for galvanic protection. AS AN OPTION , it can be installed without a zinc. Marine growth is the greatest deterrent to propeller performance. Coatings applied to a propeller do not remain effective and by the end of the season, the boat will hardly move as a result of a fouled propeller. With a "normal" bronze propeller, a zinc is installed on the stainless steel shaft to serve as a sacrificial anode. This is necessary since the bronze propeller attached to the stainless steel shaft in a saltwater environment creates a galvanic couple [a very noble metal (shaft) electrically connected to a less noble metal (prop) immersed in an electrolyte (saltwater)]. A small electric current is generated and flows from the propeller to the shaft. The electrical activity created by this current flow on the surfaces of the propeller will prevent marine growth from growing on the propeller, however the propeller will sacrifice itself and be ruined in just a couple of seasons. The addition of the zinc (a metal which is less noble than either the shaft or propeller) to the shaft prevents deterioration of the propeller as the zinc is then sacrificed. However, the propeller surfaces no longer experience the galvanic activity and thus become fouled with growth. The Silicon Bronze alloy used in the construction of the Indigo propeller gives the best of both worlds. The material is such that the propeller can be installed without a sacrificial zinc and therefore generate a controlled amount of galvanic activity and thus stay clear of marine growth. With this low level galvanic activity there is still some very minor sacrificing occurring on the surfaces of the propeller but the deterioration is greatly reduced. It is estimated that an Indigo propeller installed in this manner will have a service life of about 6 years. View actual un-edited images of an Indigo propeller after six months immersion in salt water (April - October 2002). More Propeller Images (65k)

Additional Conditions - If installing the propeller without a zinc, two conditions must be met to insure proper life of the propeller ... 1. You must install a Galvanic Isolator in conjunction with your AC shore power installation if you have AC shore power. This will eliminate stray electrical currents which can ruin a propeller in just one season. Damaged Propeller 2. If your propeller is supported by a strut or if there is more than 1 inch of exposed propeller shaft, you must paint all but 1 inch of that shaft with an insulating paint such as Glyptal 1201 or a layer of fiberglass tape. This will limit the amount of galvanic activity by limiting the area of exposed stainless steel. You would not paint the stainless steel nuts.

Download Installation Instructions

Send your questions or comments to me at tomstevens2525@gmail.com

| Home | Ignition | Oil Filter |

Crankcase| Tensioner |

Thermostat